BMW M20 6CYL ITB KIT ASSEMBLY INSTRUCTIONS

RHD PERFORMANCE UPGRADE

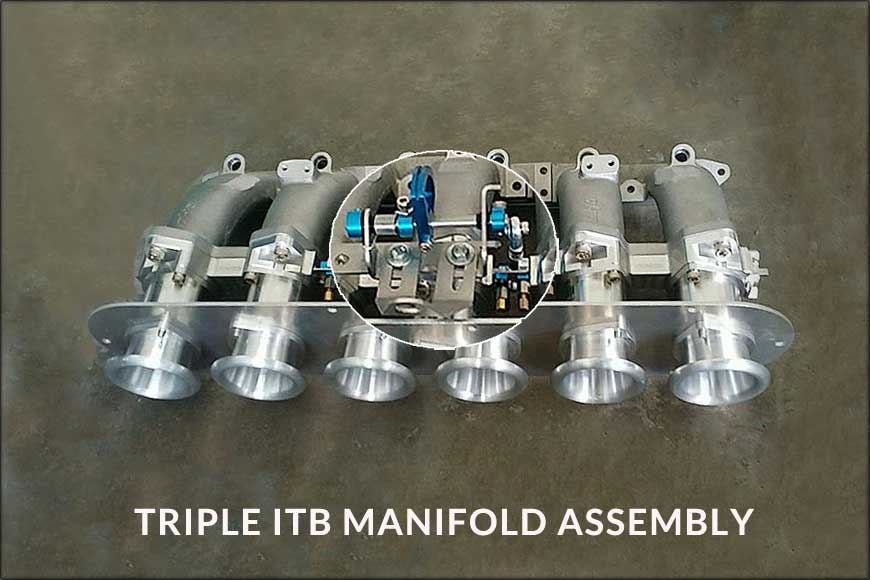

ASSEMBLY ITB BMW M20 6 CYLINDER

Thank you for choosing an RHD product. All RHD parts and products are designed for performance and racing purposes, what you do with your vehicle is your responsibility and no liability will be taken by RHD Engineering for your actions.

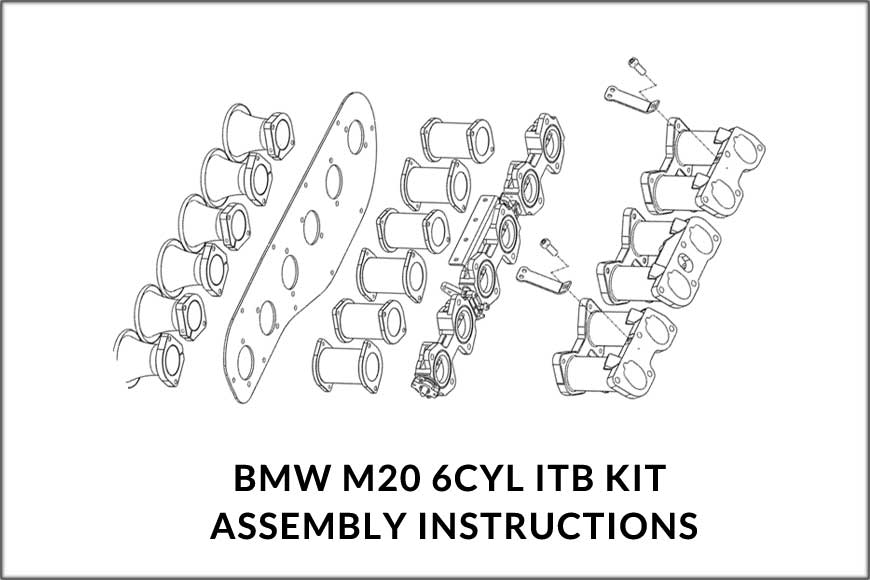

IMPORTANT! Air box or plenum fitment, please read the separate instructions for fitting details.

For this kit to work on Left Hand drive vehicles you will need a slightly longer throttle cable we suggest a 318 4cyl e36 cable. Part #35411162482 This will suit both e30 and e36 vehicles.

TPS, All 6cyl ITB kits use an original E36 BMW tps. Part # 13-63-1-726-591-M375

Installing a standalone ecu is recommended however there are other options with plenums now available for all our kits so we recommend some discussions with a local engine tuner to assess your requirements.

To install and set up this kit correctly you will need a basic understanding of mechanical devices and the appropriate mechanics tools. Please check all the parts are included and contact us immediately if you have any pieces missing.

Your kit should include the following parts:

Manifold 3 pcs

40 or 42mm ITBs 3 pcs

Trumpets and flanges 6 sets

Trumpet spacers 6 pcs

50mmx2mm O rings 18 pcs

Linkage brackets 3 pcs

M5 drop link set 1 set (2 rod ends, 2 nuts, 1 brass link, 2 cap screws, 2 washers))

Spring balance adjuster 2 pcs

Flat arm coupler 1 pc

TPS fixing plate and screws 1 pc

Cable wheel 1 pc

ITB master lever set 1 set (Idle stop, m4 screw, secondary return spring)

Universal lever long 1 pc

8mm linkage shaft 1 pc

Return spring set (3pc) 1 set (1 spring , 2 locking bosses)

M5 x 12 Hex bolts 2 pcs

Fuel rail mounts and bolts 2 pcs

9 port vacuum block 1 pc

8mm x 1/8 bsp hose tails 11 pc

8mm x 1/4 bsp hose tail 1 pc

12mm x 1/4 bsp hose tail 1 pc

Tee fitting 1/4 bsp MMF 1 pc

6mm x 1/8 bsp hose tail 1pc

4mm x 1/8 bsp hose tail 1 pc

16mm x 3/8 bsp hose tail 1 pc

M8 x 25 cap screws 12 pcs

M6 x 20 cap screws 24 pcs

M5 x 20 cap screws 6 pcs

Assembly:

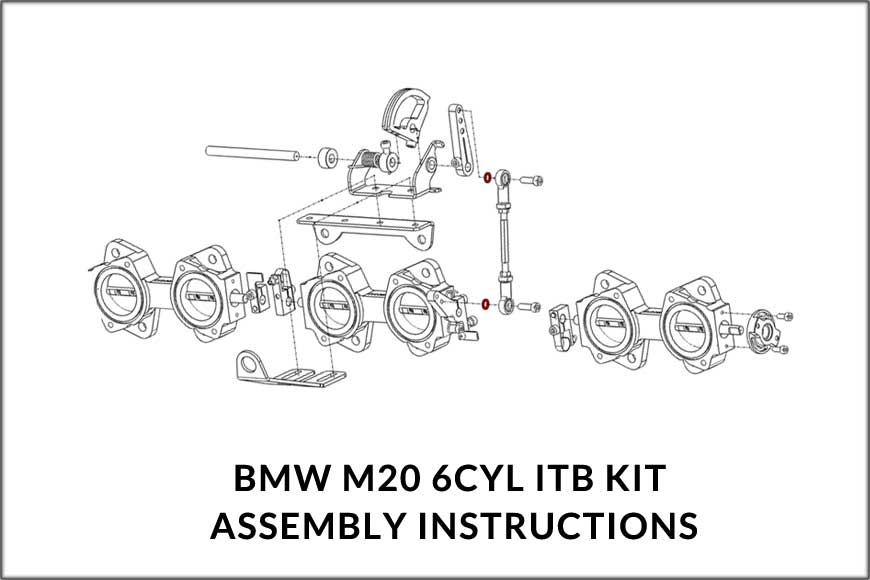

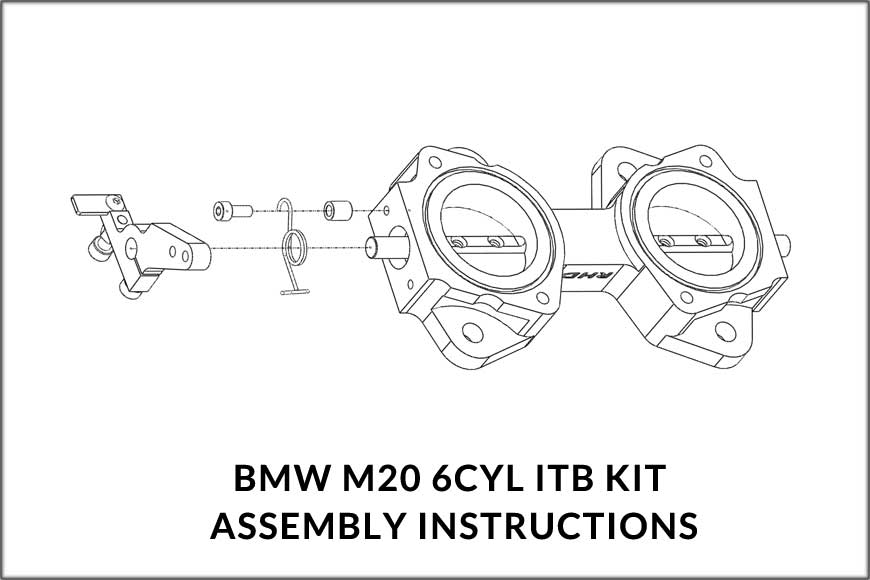

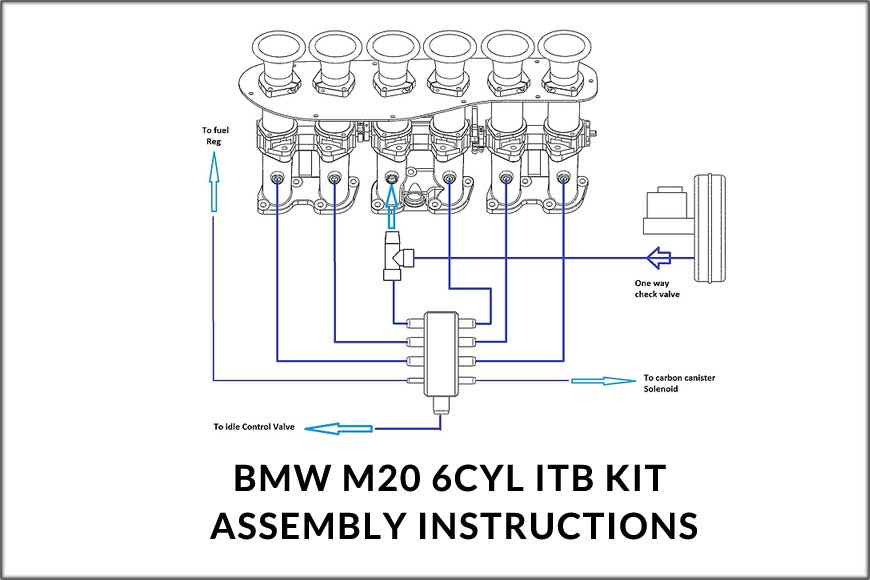

Please study the following drawings very closely they show the EXACT placement of all the fittings and linkage parts

Note: there are small washers required UNDER the m5 rod end drop link parts this is essential to allow the m5 rod end bearing to have enough clearance as the linkage moves through its travel.

The small return spring on the master ITB is only intended as a SECONDARY spring to ensure the throttles close should any linkage part becomes loose or disconnected. A second main return spring is included this can be pre-loaded up to a maximum of 180 degrees to add the desired amount of pedal resistance.

For nice progressive throttle action keep the drop link as long as possible. However if your ITB does not reach full throttle when the pedal is fully depressed then adjusting the brass drop link to a shorter length and resetting the cable slack will alter the mechanism gain and will enable the throttle to reach full open.

Make sure the linkage moves freely and smoothly without any binding. It is important the ITB linkage doesn’t reach full throttle when there is still extra travel on the pedal this will over load your cable and ITB linkage resulting in possible damage or premature failure.

Note: For your brake booster operation you will need to attach the vacuum hose to the fitting provided on the manifold. The booster will work exactly as it did before running from just 1 cylinder. The vacuum from 1 cylinder is much stronger than the signal from the vacuum accumulator block! It is recommended that the small plastic 1-way valve fitted to the factory booster line is maintained.

After installation you must adjust the throttle synchronization, this is EXTREMELY sensitive and essential for smooth idle and light throttle driving. To do this you will need the use of a synchronizer such as the one pictured below.

Open the idle stop screw until the engine is running at lease 1200rpm then fit the synchronizer to each trumpet adjusting the balance couplings until the flow into each runner is the same. Then adjust the idle stop back down to the desired idle speed.